|

|

Post by resinslinger on Apr 14, 2007 10:40:06 GMT -5

I am wondering if there would be any interest in having me post a mold making and resin casting tutorial (with pictures) on the forum? If so, I wouldn't be able to do until after the Desert Scale Classis III show on the 28th but I'd be more than happy to do so if there is enough interest. CB

|

|

|

|

Post by The Mad Modeller on Apr 14, 2007 16:05:24 GMT -5

I say go for it Chris. I have been thinking about trying my hand at it but just a lil leary in doing so.

|

|

|

|

Post by 46achers on Apr 14, 2007 18:17:27 GMT -5

You'd best dig out the camera, I know I would be interested.

Dave

|

|

|

|

Post by 67impala427 on Apr 14, 2007 21:11:36 GMT -5

I'd be very interested in it.. I've been wanting to try my hand at this.

Alex.

|

|

Rollsbug

Junior Member

Don't know what I am doing and having fun doing it

Don't know what I am doing and having fun doing it

Posts: 119

|

Post by Rollsbug on Apr 22, 2007 15:59:58 GMT -5

Sounds cool, please post!! Steve  |

|

|

|

Post by greg40515 on Apr 22, 2007 20:03:43 GMT -5

I agree, i, like a lot of others, would like to try this.

|

|

|

|

Post by 67impala427 on Apr 27, 2007 2:12:59 GMT -5

Well Chris, the ball's in your court now.

Alex.

|

|

|

|

Post by whtchevy on Oct 6, 2007 9:46:35 GMT -5

Please do, I want to learn how to do this so bad...Click Away

|

|

|

|

Post by moparmissle on Oct 8, 2007 18:30:21 GMT -5

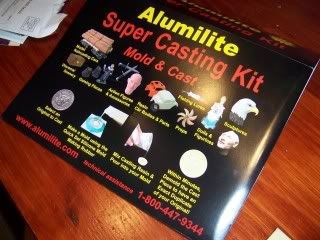

I'd love to see this. SOme people have told me about small kits at craft stores but I haven't seen these kits yet. I would love to start making some smaller things then maybe work up to bigger stuff.

|

|

opa1

Junior Member

Posts: 133

|

Post by opa1 on Oct 8, 2007 20:39:59 GMT -5

Me too. I am realy interested in both processes. It would be great to learn the steps to both instead of trial and error. We'll be waiting.......  ED  |

|

|

|

Post by lilmanlovesmustang on May 23, 2009 7:50:27 GMT -5

i want learn tooo,

thanks

mike

|

|

|

|

Post by Eddie on May 23, 2009 8:30:44 GMT -5

Yes please. I would love to learn to do this. I even bought a kit but as I got promoted at work late last year I haven't had time to even open it. I hope to rectify this soon.

|

|

|

|

Post by willysurvive on May 23, 2009 9:35:42 GMT -5

Man I'd love to know how to cast a set of wheels or an air cleaner. Just little stuff for now. But yeah i'd be super interested in this especially since I got laid off I have more time to do everything. Thanks in advance.

|

|

|

|

Post by coopdad on May 23, 2009 10:55:13 GMT -5

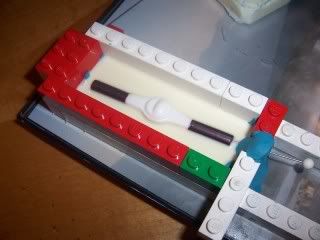

I will throw in my experience casting parts. I am no expert but have had pretty good luck. The basic process is pretty easy (but perfecting it takes practice): make a part to cast, make a mold of it, then cast the part. I used a all-in-one kit available at local hobby stores/Michaels/Hobby Lobby for about $70. It has all the stuff needed to cast parts.  In this example I cast a set of wheels that I modified for wider tires. You stick the part to a flat surface (a CD case in my example) using glue or the clay that comes in the kit. Then you need to build a box around the part to hold the molding RTV material... Legos work great as they are handy and you can make just about any size box.  Then mix the molding RTV liquid according to the kit's directions and slowly pour into the lego box. To help reduce the introduction of bubbles into the mold you should pour far away, not on the part. I also use a "bubble reduction device" (my daughter's old electric toothbrush) to vibrate the bubbles to the top.   After a few hours the mold will be hard and the parts can be removed.   Now on to the casting. A very similar process... mix the casting resin up according to the directions and pour into the (microwave warmed) mold. Again, don't pour directly into the mold, let it run in because it helps limit the number of bubbles in the final part. Sorry, no pix of the pouring as the resin in the kit hardens VERY quickly (less than a minute). After the resin if fully hardened, you can remove your new wheels!  This process is a one-part mold since the there is only one part to the mold. A two part mold can also be made for complicated, 3-D parts. The process is the same only you suspend the part above the flat surface, pour the first mold and let it harden. Then coat it with a special nonstick liquid (also supplied in the kit) and then pour the second half of the mold.  I have found that making small parts like seats, axles, wheels, etc. using one part molds is very easy. By doubling the number of molds increases the complexity of the process... you have to plan for where you will be pouring in the resin. And some shapes will require you cut in air vent holes or huge bubbles will show up in you final part. Also, the larger the part the more difficult it becomes. I tried to cast a car body and the results are marginal at best. I found that so much molding RTV is needed that it became very expensive very quickly. I have also found that Hobby Town occasionally has coupons that will help reduce the cost of the kit. Watch the newspapers. Again, I am no expert, have made 20-25 molds, and I am still learning. Hope this helps. John |

|